OMCO Foundations

Accommodates challenging soils

Compatible with OMCO Solar mounting systems

Factory=direct shipping for short lead times

Quick, easy installation

Cost efficient

Quality assurance

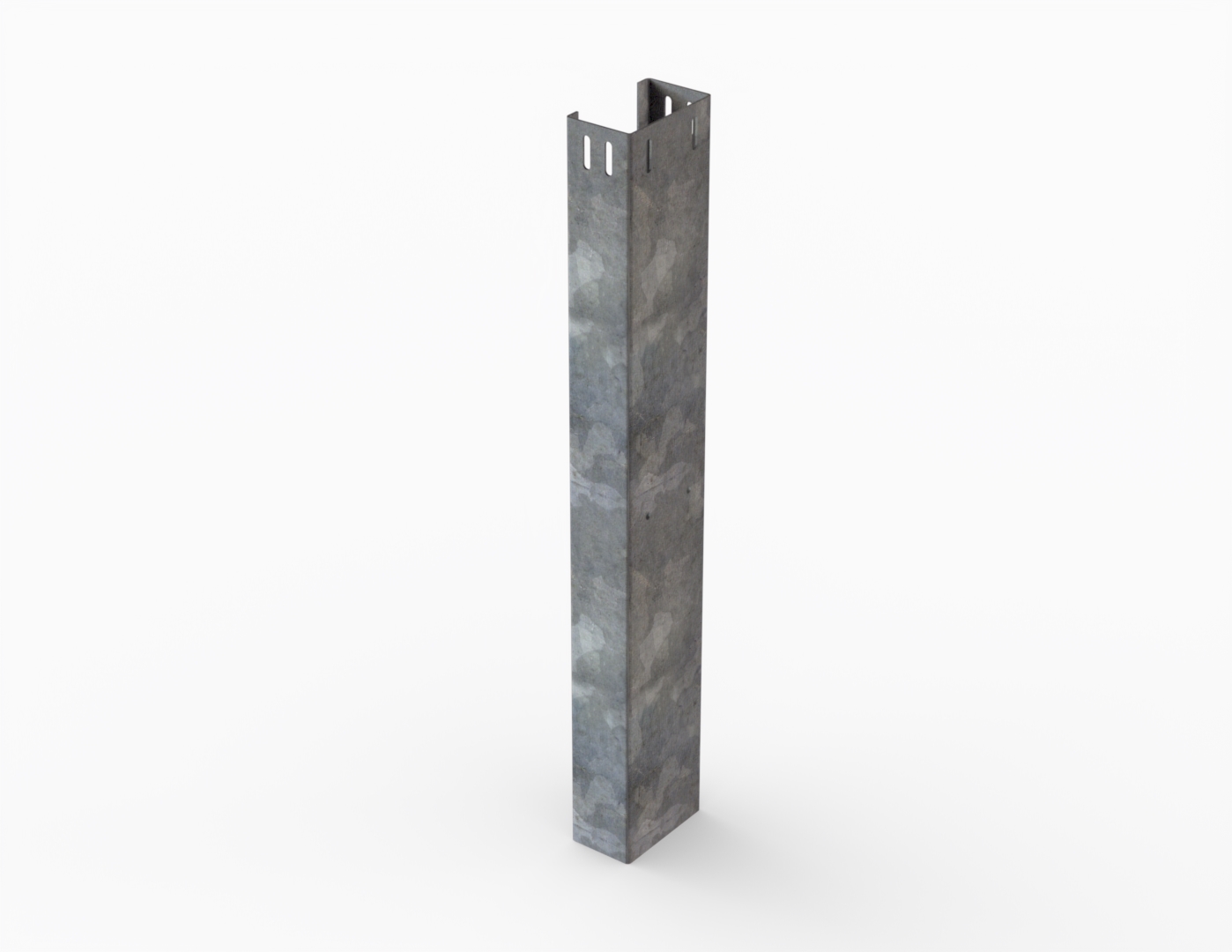

OMCO C-Pile Foundation

Driven piles for ground mount solar structures are one of the most ideal foundation types. OMCO’s C Piles have been designed to offer significant advantages that make them the number one choice for your project. Driven piles are less expensive to manufacture and install.

All piles are made in our U.S. manufacturing facilities – roll-formed from high yield strength steel, with holes and slots added inline, and pre-galvanized with a G235 zinc coating. A more uniform and reliable service life than the standard hot dipping process which is an expensive and environmentally challenging operation.

The OMCO C Pile offers a higher moment of inertia than typical W Pile sections which reduces deflections and ultimately embedments in some cases. A higher section modulus equates to higher resistance to bending as well.

Pile Durability

- HIGH PULL STRENGTH

- 2X RESISTANCE TO BUCKLING

- 2 GAUGE OPTIONS FOR OPTIMIZED SPANS

- CROSS-SECTION AREA = DRIVABILITY

- PILE PERIMETER IMPROVES UPLIFT RESISTANCE

OMCO Ground Screw Foundation

OMCO Solar knows the importance of eliminating subsurface risks on ground mount projects to ease installation and avoid added cost. That’s why we’ve taken lessons learned in developing our industry- leading mounting structures and incorporated the same winning advantages into our Ground Screw Foundation.

Working with trusted and industry respected suppliers, our solution for incorporating ground screw foundations is custom built for developers and EPCs.

We understand the challenges of sites with difficult soils or shallow bedrock, particularly in the Northeast. Ground screws eliminate pile refusal so your project can progress quickly to meet deadlines within budget.

Smooth Installation

- MEETS ALL SITE LOADING REQUIREMENTS

- ELIMINATES PILE REFUSAL

- INFINITE ROTATIONAL ADJUSTABILITY AFTER SCREW IS SET FOR OPTIMUM POST ALIGNMENT

- 21 INCHES OF VERTICAL ADJUSTABILITY PROVIDES FLEXIBILITY

- USING SPECIAL DRIVERS, EACH TEAM CAN INSERT AS MANY AS 30 FOUNDATIONS / HOUR

Technical Specifications

LENGTH

Available in either 1600 mm or 2000 mm

OUTER DIAMETER

76 mm

THICKNESS

3.00 mm

THREAD DEPTH

880 mm

CONSTRUCTION

Q235B steel

Continuous welded helix for screw threads.

Galvanized to ASTM123 75 micron.

Screw extension component provides easy vertical adjustability.

Standard M12 bolts supplied to make connections to OMCO’s factory-direct structures above the screw.

LOAD CAPACITY

Appropriate screw diameters and lengths chosen for each site, to meet all applicable building codes, wind tunnel requirements up to 180 mph, and snow loads up to 90 psf.

General load capacities from ICC-ES Evaluation Report ESR-4226 load charts and frost depths for the site used to identify the initial length for quoting.

TESTING

On-site ground screw load test recommended for all projects to verify design capacities for each screw length.

OMCO’s in-house testing capabilities and engineers can quickly evaluate all data and provide updated pricing and construction documents to meet project specifications.

UL 2703 compliant

TERRAIN ARTICULATION

Structures can follow the terrain up to approximately 15%.

WARRANTY

20-year limited