OMCO Origin®

Factory-Direct Trackers

Overview

OMCO Origin Factory-Direct Trackers are designed for quick, easy and safe installation, and fewer trackers per MW. With fewer controllers and motors per MW, our single-axis tracker system delivers cost-effective solar energy solutions from lower tracker cost and commissioning expenses to reductions in operations and maintenance costs overall.

OMCO Solar designs and manufactures One-In-Portrait (1P) solutions to meet the needs of a wide range of solar projects for utility scale, distributed generation (DG), and community solar markets. We offer full-scale support including geotechnical, structural, installation, and commissioning, making 1P solar tracker deployment seamless. Whether for traditional solar farms, emerging agrivoltaics applications, or meeting the energy demand to support data centers, our advanced solar solutions ensure reliability and efficiency in tracking the sun for maximum energy output across current and up-and-coming markets within the US.

Foundation Solutions

for Every Terrain

- OMCO C PILES

- GROUND SCREW ASSEMBLY

- SOURCED W PILES

Premium Features

Solar Proven Bearing Materials

6 Dimensions of Adjustment

Made in the USA

Balanced Design

Long Wear Life

Quick Installation

Labor-Saving Bearing

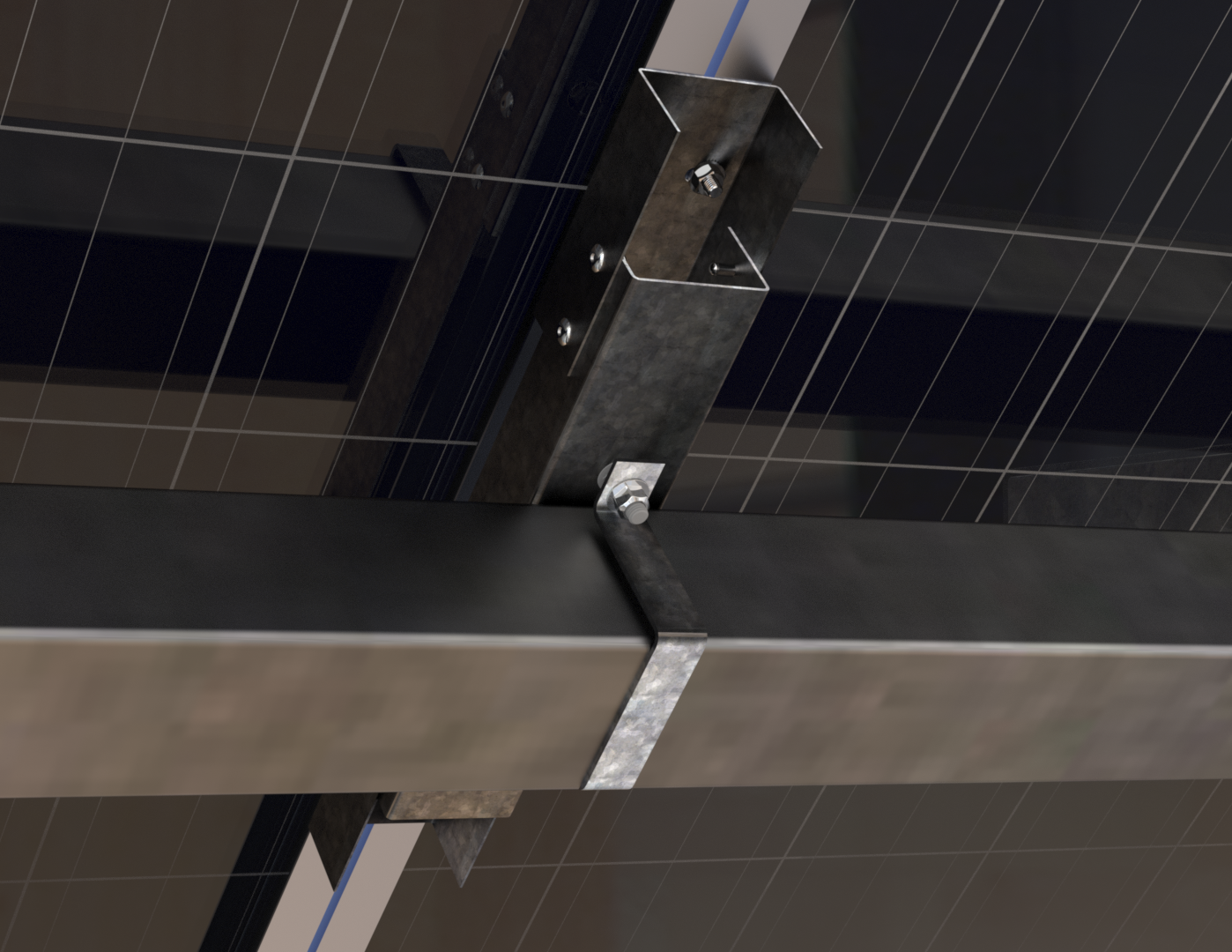

The OMCO Origin bearing features a unique problem-solving design that can eliminate major costs and delays due to poor post placement. This innovative bearing adjusts 6 ways to accommodate post misalignment without requiring an expensive post re-install and ensuring ease of tracker installation especially across undulating terrains.

OMCO Origin bearings are factory preassembled and shipped as a single unit, in a “nominal” position with all adjustment features in the middle ranges, streamlining setup on site.

- Factory preassembled

- 6 adjustable ways to compensate for posts and terrain issues

- Low friction, self-lubricating design for long wear life that contributes to the reliability of our high-performance tracker

OMCO Origin One-In-Portrait Trackers

Mounting Options for all Commercially Available Modules

First Solar Series 6/6+

First Solar Series 7

Large Format/Bifacial

Design for Fast, Easy and Safe Installation

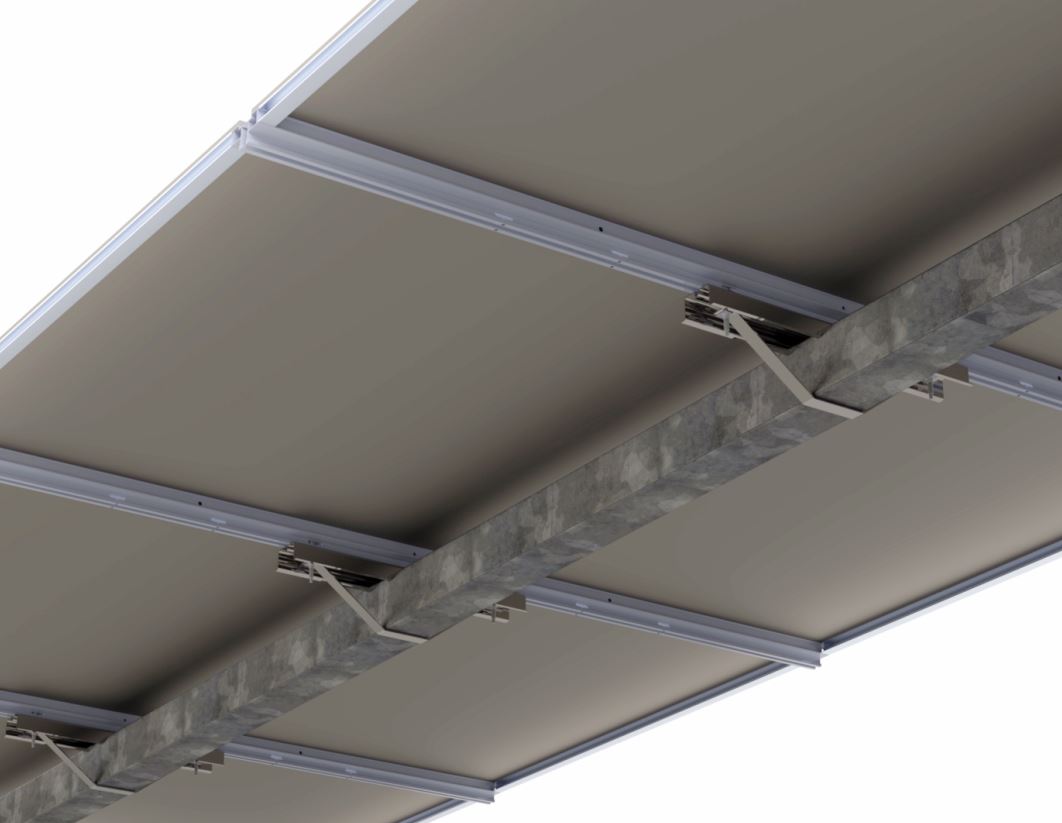

The preassembled module mounts for OMCO Solar’s One-in-Portrait (1P) solar tracker systems can be installed on the torque tube at any spacing, accommodating modules of any size and weight.

These capabilities allow the OMCO Origin single-axis tracker to utilize standard production parts to mount all framed modules and First Solar’s Series 7, eliminating the need for custom orders and the associated project delays. With solar tracker efficiency in mind including simplifying installation and reducing labor costs, our cost-effective solar energy solutions put the manufacturing power into your hands.

- Factory preassembled for faster installation and lower costs

- Fasten from below – no ladders needed, both feet on the ground for improved safety and faster install

- Minimal module spacing – high Ground Coverage Ratio (GCR)

Technical Specifications

Tracking Technology

TRACKING RANGE

MODULES AND CONFIGURATIONS

Monofacial and bifacial modules

Framed silicon module – Up to 120 per tracker

First Solar Series 6 & Series 7 modules – Up to 96 per tracker

DIMENSIONS

Width – Modules horizontal – 2.0 m (6.5 feet)

Length – Up to 122 m (400 feet)

FOUNDATIONS

Driven I or W posts – OMCO sourced

OMCO Ground Screw Foundations

STRUCTURAL MATERIALS

DRIVE

20 drives per MW (typical)

MOTOR

20 motors per MW (typical)

CONTROL SYSTEM

DC with 30 or 60-watt module and long-life LiFePO4 battery

AC up to 264 vac input

1 network controller per 100 – 150 trackers (wireless)

1 or more meteorological stations per site

1 remote access unit per site – datalogger and modem

COMMUNICATION

Network controller to SCADA: MODBUS TCP/IP over ethernet

Cloud app available for remote monitoring and predictive maintenance

STEP SIZE

TRACKING ALGORITHM

Tracking accuracy ± 2°

BACKTRACKING

NIGHT STOW

WIND STOW

SNOW STOW

SNOW SENSOR

FLOOD SENSOR

BEARINGS

Adjustable in multiple dimensions to take up post misalignment

Delivered fully assembled from the OMCO Solar factory

NORTH-SOUTH SLOPE

INSTALLATION

COMPLIANCE

WARRANTY

Control System: 5 years standard, 10 years optional

Drive: 5 years

Motor: 5 years

Dampers: 4 years